Tapered Roller Bearings have revolutionized modern machinery by enhancing efficiency and performance across various industries. These bearings reduce friction, which prevents heat buildup that can lead to structural failure. Their unique design allows them to handle both radial and axial loads, making them indispensable in applications ranging from automotive to heavy machinery. The market for these bearings is experiencing significant growth, projected to reach USD 5 billion by 2028, with a CAGR of over 6% from 2023 to 2028. This growth underscores their critical role in advancing industrial capabilities.

Early History and Invention

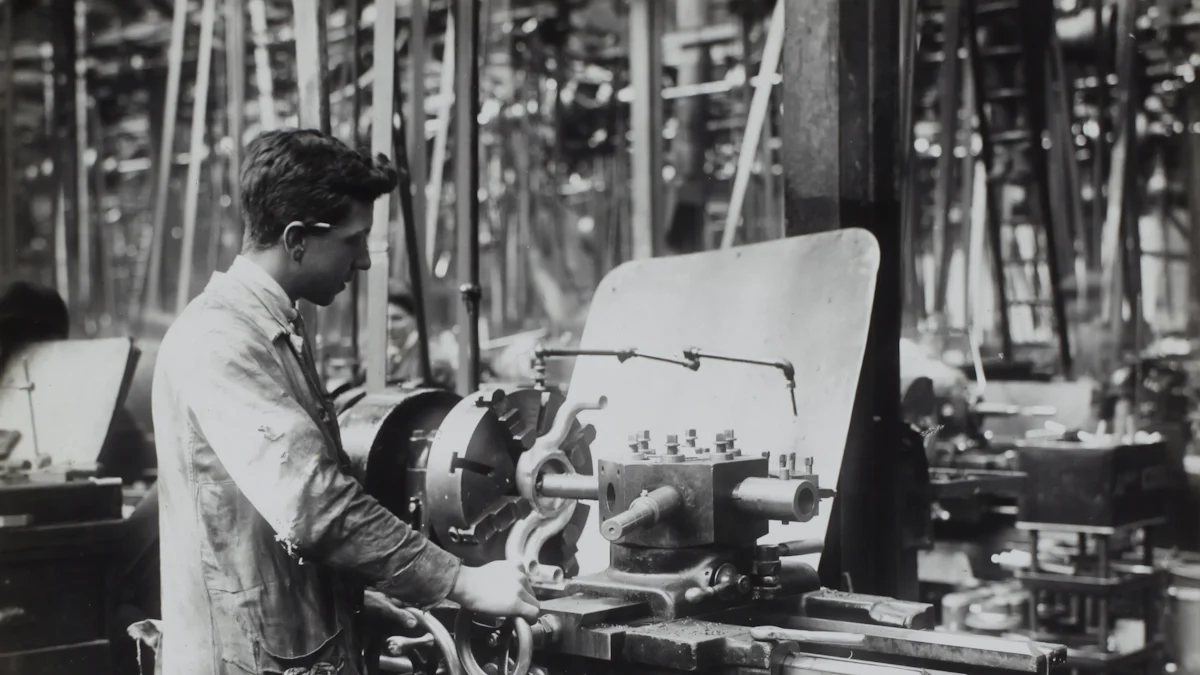

The Origins of Roller Bearings

John Harrison’s Contributions

In the 1740s, John Harrison made a groundbreaking contribution to the world of mechanics by creating the first known tapered roller bearing for his H3 marine chronometer. This invention marked a significant leap in precision engineering. Harrison’s design aimed to reduce friction and enhance the accuracy of timekeeping at sea, which was crucial for navigation. His work laid the foundation for future developments in bearing technology, showcasing the potential of roller bearings in various applications.

Early Designs and Concepts

The concept of roller bearings evolved over time, with early designs focusing on reducing friction between moving parts. These initial designs featured cylindrical rollers that distributed loads more evenly than traditional ball bearings. Engineers and inventors experimented with different materials and configurations to improve performance and durability. These early concepts paved the way for more advanced designs, including the Tapered Roller Bearing, which would later revolutionize multiple industries.

Henry Timken and the Birth of Tapered Roller Bearings

Timken’s Innovations

Henry Timken played a pivotal role in the development of the Tapered Roller Bearing in the late 19th century. His innovative design addressed the limitations of existing bearings by allowing them to handle both radial and axial loads efficiently. Timken’s invention significantly improved the performance of conventional bearings, reducing friction and enhancing reliability. This innovation proved particularly beneficial in the transportation industry, where it reduced repairs and improved wagon performance.

The First Patents and Commercialization

Timken’s groundbreaking work led to the foundation of The Timken Company, a testament to the impact of his invention. He secured patents for his Tapered Roller Bearing, which laid the groundwork for the company’s success. The Timken Company quickly became one of the most successful global family businesses in the United States. Timken’s patented design contributed to the development of various forms of rolling bearings, cementing its place in bearing history. Today, Tapered Roller Bearings remain reliable and efficient, widely used across numerous industries.

Design and Functionality of Tapered Roller Bearings

Unique Features

Load Distribution and Efficiency

Tapered Roller Bearings excel in distributing loads efficiently across their tapered surfaces. This design allows them to handle both radial and axial forces with remarkable effectiveness. The tapered geometry ensures that loads are spread evenly, reducing stress on individual components. This feature enhances the bearing’s ability to operate under high loads and vibration stresses, making it ideal for demanding applications. By minimizing friction and heat generation, these bearings prevent structural failures, ensuring longevity and reliability in various machinery.

Versatility in Applications

The versatility of Tapered Roller Bearings stems from their ability to support diverse forces. They find use in a wide range of applications due to their adaptability. These bearings can sustain large axial and radial forces, making them suitable for both low-speed, high-load scenarios and more dynamic environments. Their robust design allows them to perform reliably in challenging conditions, such as those found in heavy-duty industrial settings. This versatility makes them indispensable in industries where performance and durability are paramount.

Common Applications

Automotive and Transportation

In the automotive and transportation sectors, Tapered Roller Bearings play a crucial role. They are commonly used in vehicle wheel hubs, transmissions, and differentials. These bearings enhance the performance and safety of vehicles by providing stability and reducing wear and tear. Their ability to handle both radial and axial loads ensures smooth operation, even under the stress of high-speed travel. This makes them a preferred choice for manufacturers aiming to improve vehicle efficiency and longevity.

Heavy Machinery and Equipment

Tapered Roller Bearings are essential components in heavy machinery and equipment. Industries such as construction, mining, and paper mills rely on these bearings for their high load-carrying capacity and stability. They are designed to withstand the harsh conditions often encountered in these environments. Proper lubrication is critical to their performance, ensuring smooth operation and extending their lifespan. Their robust construction and ability to absorb significant forces make them ideal for heavy-duty applications where reliability is non-negotiable.

Industrial Impact and Advancements

Evolution Over Time

Technological Improvements

Tapered Roller Bearings have undergone significant technological advancements over the years. Precision grinding techniques have enhanced the accuracy of these bearings, ensuring smoother operation and reduced friction. Heat treatment processes have improved their durability, allowing them to withstand extreme conditions without compromising performance. Surface coating technologies have further increased their resistance to wear and corrosion, extending their lifespan in demanding environments.

Recent innovations include sensor-integrated bearings, which provide real-time data on bearing performance. These sensors enable predictive maintenance, reducing downtime and preventing unexpected failures. Advanced lubrication systems have also been developed, ensuring optimal performance by minimizing friction and heat generation. These technological improvements have made Tapered Roller Bearings more reliable and efficient, meeting the evolving needs of modern industries.

Adaptation to Modern Needs

Industries today demand bearings that can adapt to diverse applications and environments. Tapered Roller Bearings have risen to this challenge by offering versatility and adaptability. Their ability to handle both radial and axial loads makes them suitable for a wide range of applications, from automotive to aerospace. The construction industry relies on these bearings for their load-carrying capacity, while the mining sector values their durability in harsh conditions.

The growing demand for high-performance motorcycles and customized vehicles has driven the market for advanced Tapered Roller Bearings. Manufacturers continue to innovate, developing bearings that meet specific requirements for speed, load, and environmental conditions. This adaptability ensures that Tapered Roller Bearings remain a critical component in various industrial applications.

Role in Modern Machinery

Enhancing Performance and Longevity

Tapered Roller Bearings play a crucial role in enhancing the performance and longevity of modern machinery. Their unique design allows for efficient load distribution, reducing stress on individual components. This feature minimizes wear and tear, ensuring that machinery operates smoothly and reliably over extended periods. By reducing friction and heat, these bearings prevent structural failures, contributing to the overall durability of equipment.

In the automotive industry, Tapered Roller Bearings improve vehicle performance by providing stability and reducing maintenance needs. They enhance the safety and efficiency of vehicles, making them a preferred choice for manufacturers. In heavy machinery, these bearings support critical components, ensuring that equipment can handle high loads and operate under challenging conditions.

Contribution to Industry Standards

Tapered Roller Bearings have set industry standards for performance and reliability. Their widespread use across various sectors highlights their importance in maintaining operational efficiency. Industries such as shipbuilding, railway, and construction rely on these bearings for their adaptability and load-carrying capacity. The development of industry standards for Tapered Roller Bearings ensures consistent quality and performance, benefiting manufacturers and end-users alike.

The continuous advancements in technology and materials have further solidified the role of Tapered Roller Bearings in modern machinery. As industries evolve, these bearings will continue to adapt, meeting the demands of new applications and environments. Their contribution to industry standards underscores their significance in advancing industrial capabilities.

Tapered Roller Bearings have a rich history of innovation and development. From John Harrison’s initial designs to Henry Timken’s groundbreaking innovations, these bearings have evolved significantly. They are meticulously engineered to distribute loads evenly and withstand diverse forces in critical applications. Their superior load-carrying capacity and adaptability make them indispensable in various industrial applications. As technology advances, Tapered Roller Bearings continue to transform, driven by increasing demand across sectors. Future advancements promise enhanced performance through advanced materials and custom-designed solutions, ensuring their ongoing importance in modern machinery.

Post time: Nov-04-2024